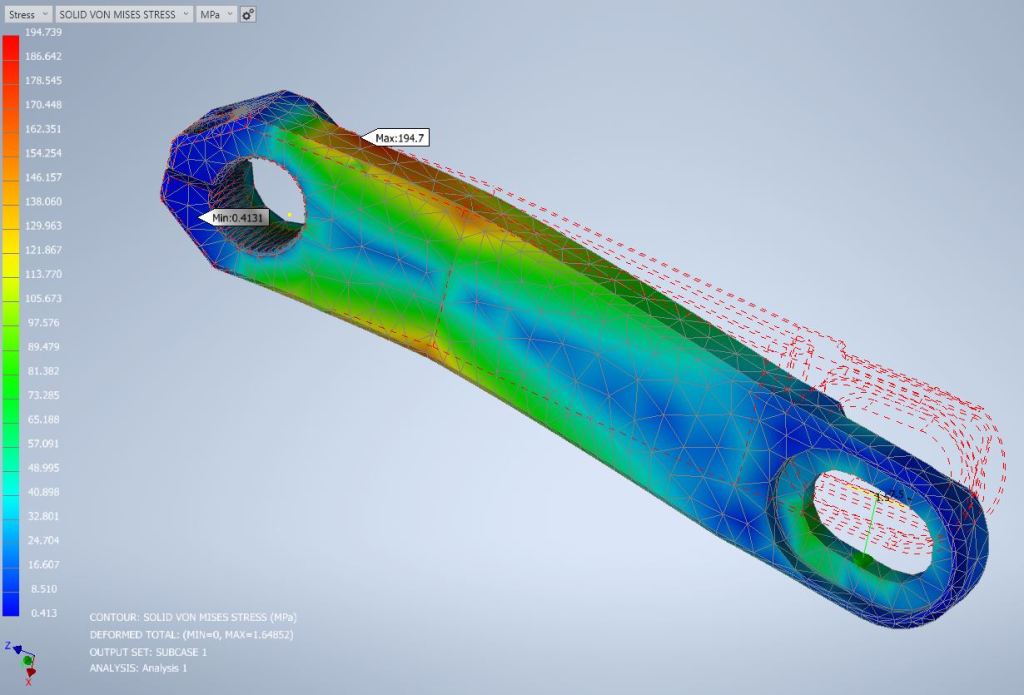

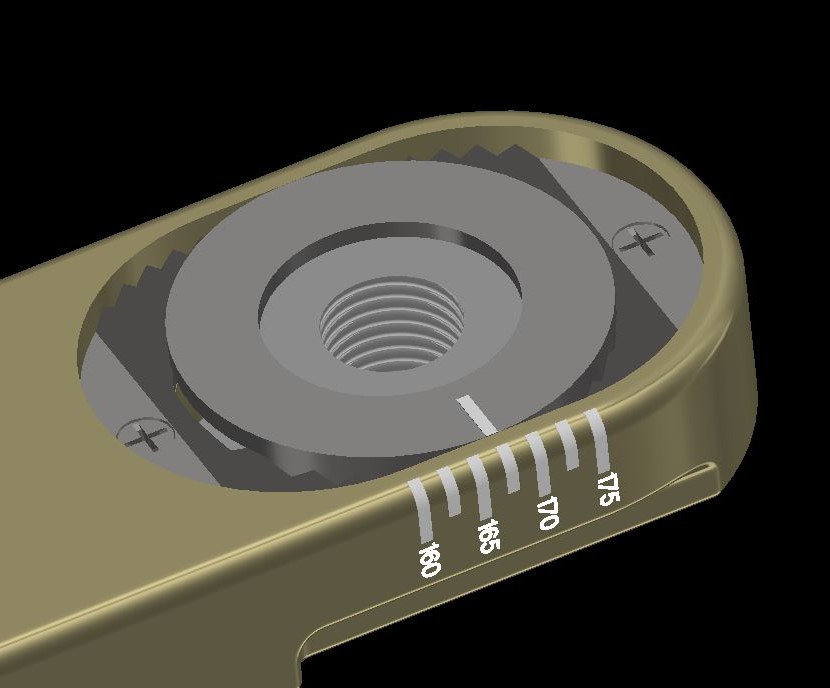

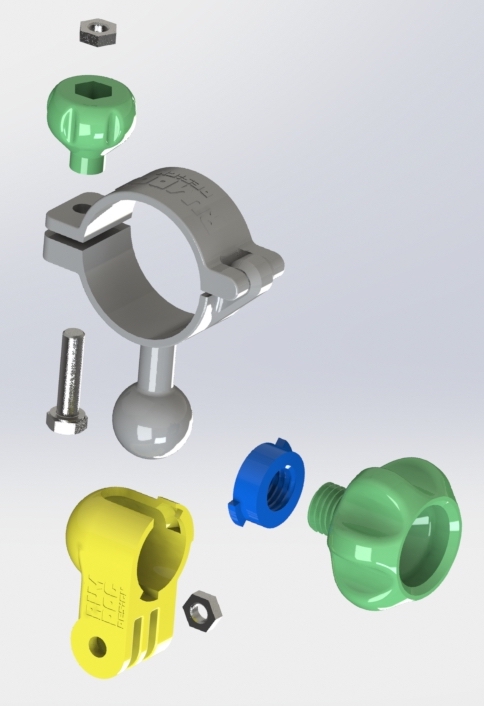

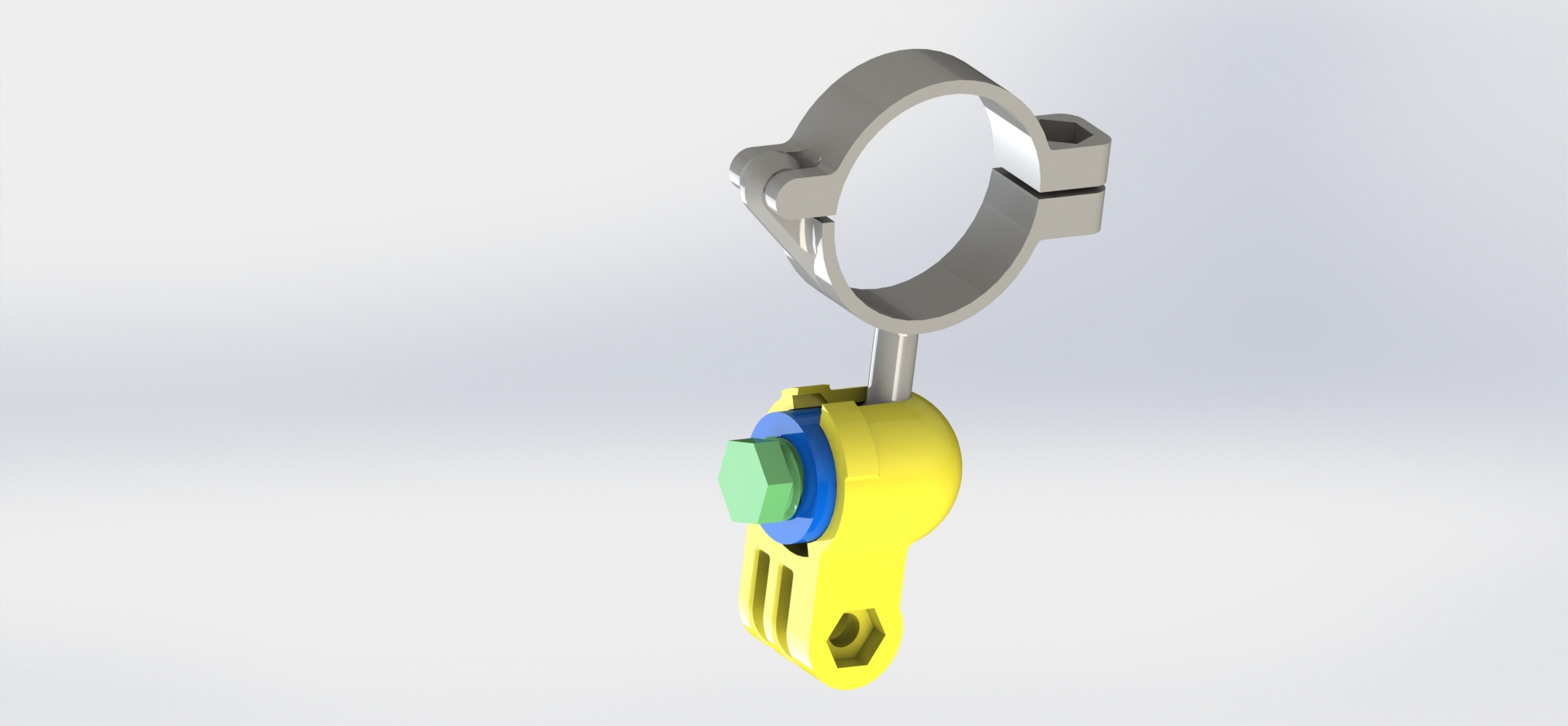

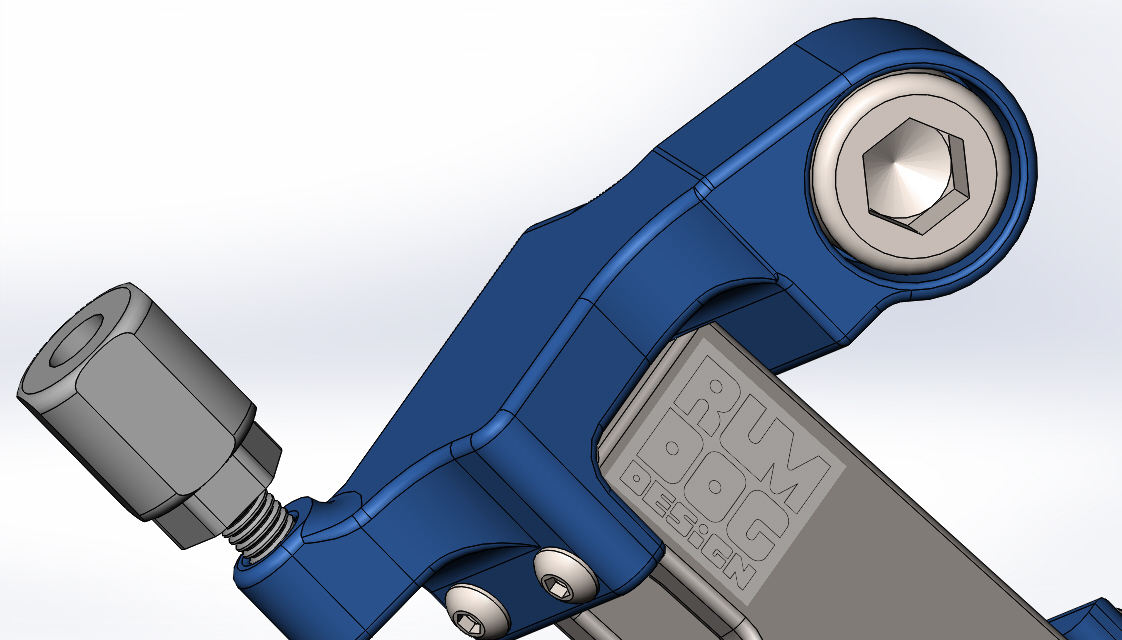

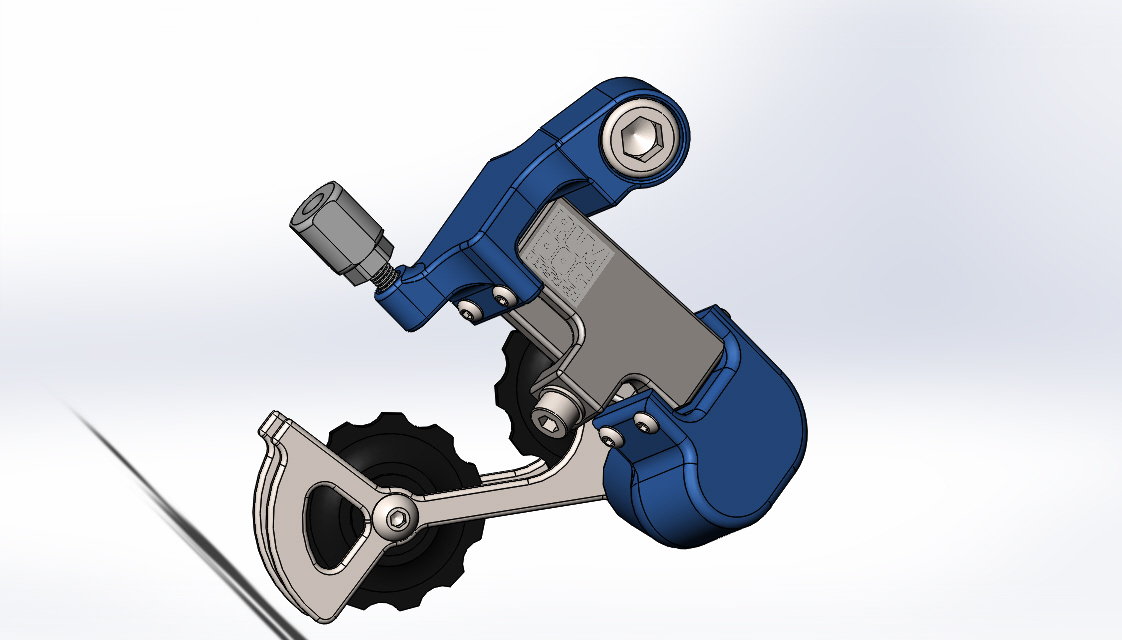

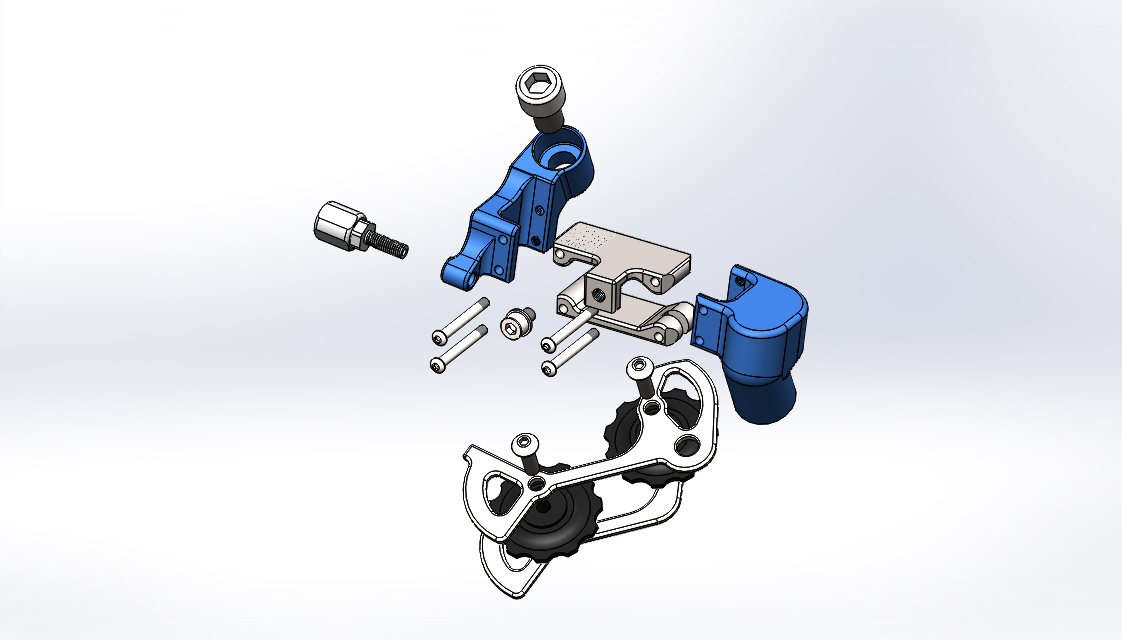

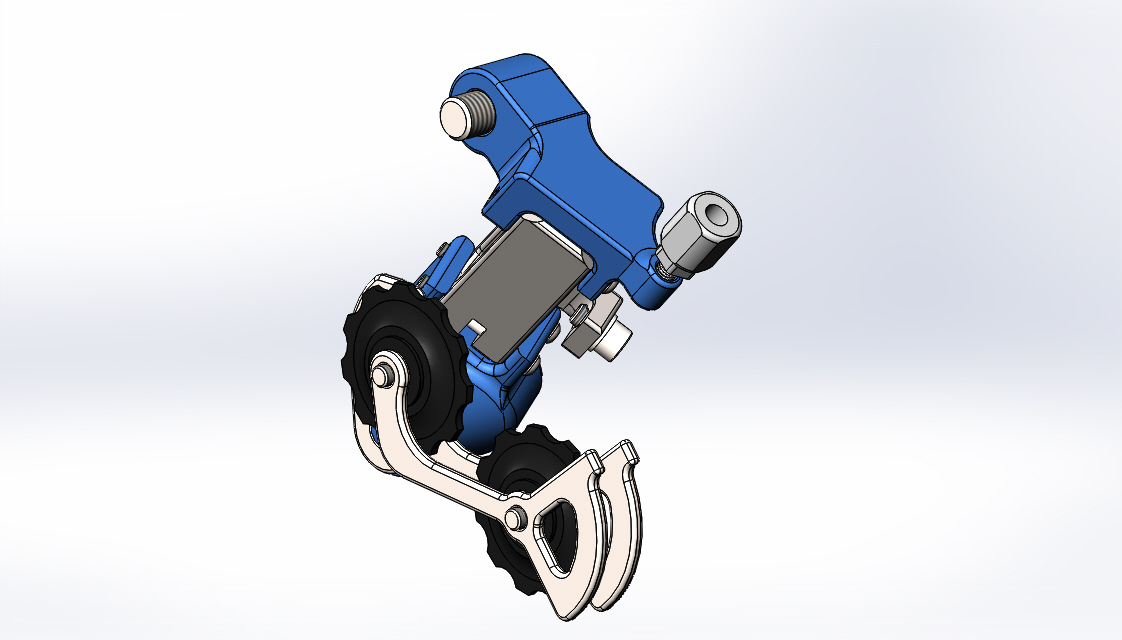

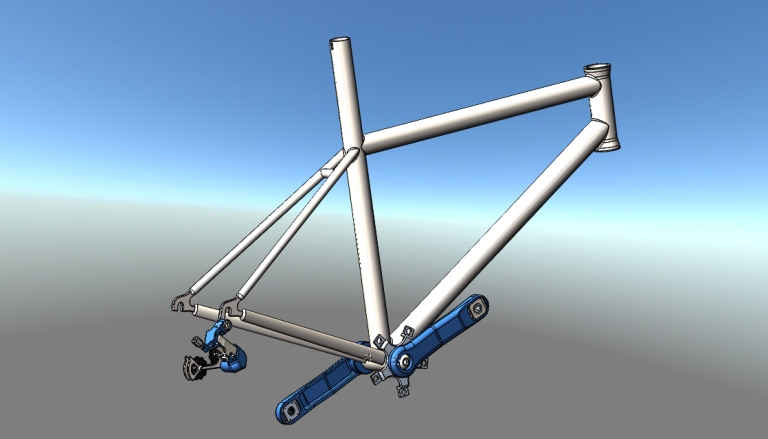

RumDogDesign is a registered trademark of CHBE Ltd. Providing engineering design services, including piping design, mechanical design. This blog shows a portfolio of 3D modelled products by Colin Bark, with over 25 years experience designing products & systems in various engineering disciplines including oil & gas, aerospace, hermetics, bicycles & shipbuilding. The site will expand to include everything from modular gear mechanisms, pedals, frames, handlebars & brakes, with some new ideas in where 3D printed components can develop in the near future.

If you like my designs or my 3D CAD skills & are currently looking for contractors in engineering design or CAD, so please feel free to view my CV & contact me via email